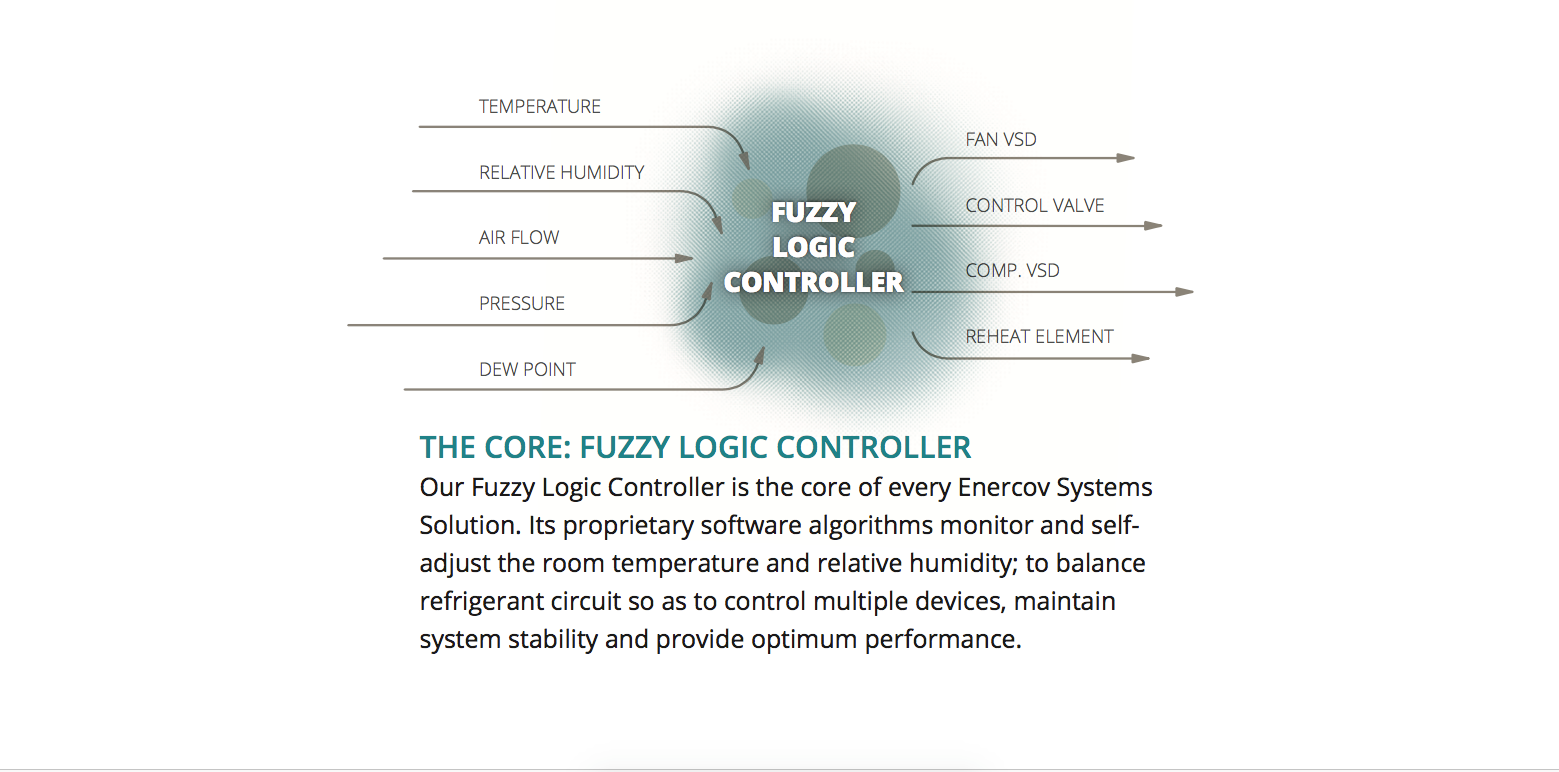

At the core of every Enercov Systems Solution is our Fuzzy Logic Controller. Enercov has undertaken extensive research on Fuzzy Logic Controller.

Our Technology

Enercov has developed proprietary software algorithms that are embedded within the Fuzzy Controller. These algorithms are able to map temperature, relative humidity and monitoring parameters within a pre-set performance operating zone giving accurate air properties control.

Our Fuzzy Logic Controller is implemented over a Digital Direct Control (DDC) Micro-processor based control framework.

Traditional Technology

Traditional PID controller technology cannot “solve” such a complex control optimization problem from a system level. It normally can control two input variables with one output variable.

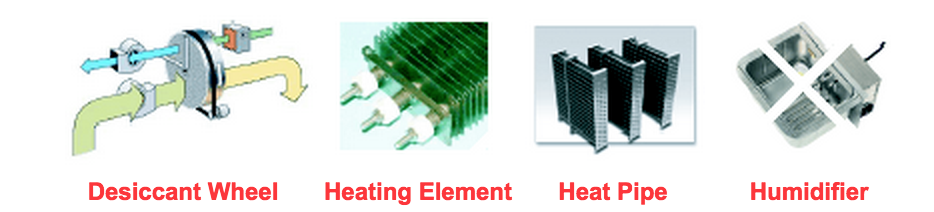

Hence, most traditional system solutions achieve air properties control using separate equipments and “cascade” them to achieve the precise level of control. The current System solutions will include one or more of these elements:

Each of these elements will have its separate controller. The net effect is a cascade of different equipments, each with its cost of acquisition, energy consumption, maintenance and other running overheads.

The end result is high capital investment and high on-going energy running cost.

Our Differentiation

We have the ability to maintain control over multiple inputs and output variables through our proprietary solid state DDC Fuzzy Logic Controller. As such, we are able to achieve precision air properties control without using desiccant wheel, heating element or heat pipe.

Our proprietary technology allows us to control the temperature and relative humidity of a single zone by varying the chilled water flow rate and the air flow rate across the chilled water coil of AHU OR changing the variable speed drive of DX compressor with DX Heat Recovery System and the air flow rate across the DX Coil of AHU. In addition, we are able to control other parameters like room air pressure, carbon dioxide level precisely.

Research and Development

At Enercov, we constantly strive to improve product design and performance. We are continually exploring new ideas and fine-tuning control technology for dehumidification applications.

In addition, new design configurations are tested in our state of the art testing facility to monitor performance under different operating conditions.

Benefits

We protect your new and existing investment. Enercov’s system solution can be implemented into your existing factory floor.

We help you to save on energy consumption. Enercov’s system solution eliminates the need for desiccant wheel or heating element, helping you to save on energy consumption.

We make you more operationally ready. Being the “intelligence” behind your precision air properties control, we are able to help you swiftly ascertain if there are any faults within the entire system solution.

Our System Solution Approach

Enercov approaches every client with the total system solution in mind. We bring in the necessary components and technologies to make the installation, on-going maintenance and post monitoring simple and easy. All our installations comes with networking capability, easy control and monitoring, as well as standard interfaces to integrate with third party solutions and software.

Easy Control and Monitoring Console

All the necessary control parameters to be monitored, such as room temperature, humidity, pressure, air flow rate, particle count or other specified parameters, can be integrated into a special Graphic User Interface (GUI) for easy control and monitoring.

The entire system components such as compressor, supply air fan, solenoid valve, VSD, pump, are linked up to a local area network (LAN). Through a computer, all the control parameters can be accessed and managed easily on or off-site. Full control routines such as the cooling function, dehumidifying function, heating function and humidifying function are provided through the computer.

An LCD serves as a simple input device for controlling key parameters.

Network Capability

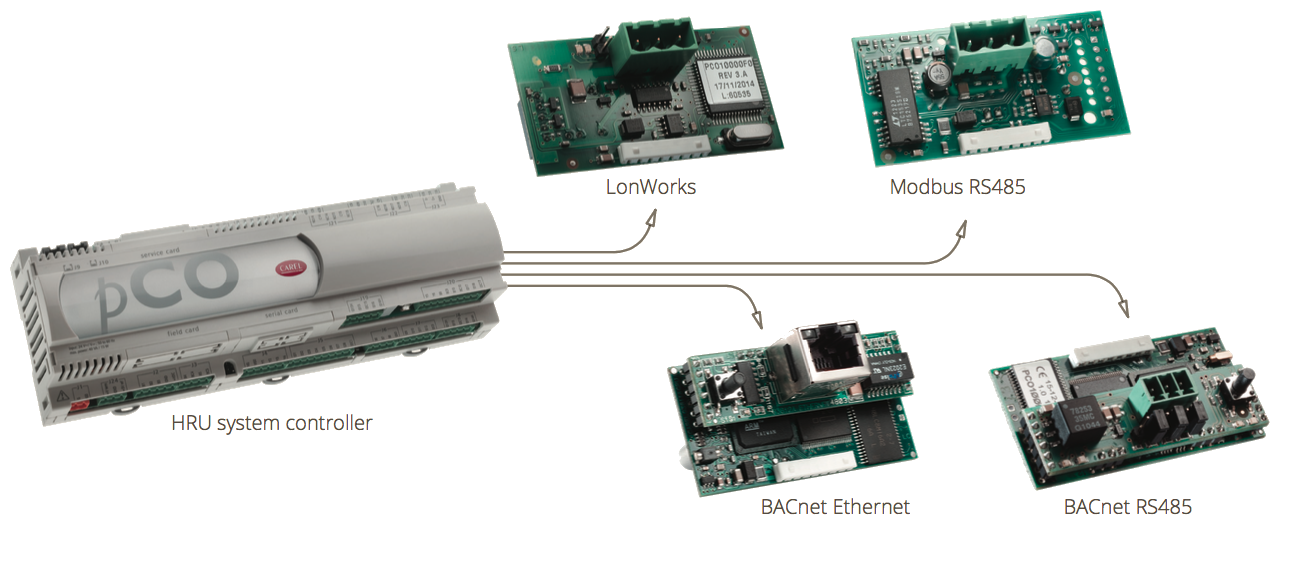

Enercov System Solution is network enabled. The various components such as compressor, supply air fan, solenoid valve, VSD, pump are connected via the local area network and can be remotely monitored even over the public telephone line. Our system solution is designed to work with communication industrial protocol standard RS485. With a connectivity speed of 19.2 kbps, we are able to gain full access to the system operating parameters allowing us to monitor and configure settings, generate reports and manage the entire System Solution easily anytime, anywhere.

In addition, to ensure a greater security and simpler maintenance, Enercov’s DDC Fuzzy Logic controllers are able to receive and send SMS messages with the integration of a simple GSM modem.

Integration with 3rd Party Software

Enercov System Solution has the standard interface that can be easily integrated into any third party monitoring software. The DDC Fuzzy Logic controller can interface with the more widely-used communication standards, either directly or via gateways (Modbus, BACnetTM, Johnson Metasys , DLL for Windows, TCP/IP, SNMP, LonWorks , Trend).